Bespoke Engineering

If it’s obsolete or no longer made, our in-house engineering team can manufacture a new part or modify an existing one. With in-house bespoke engineering facilities we can manufacture one-off or large batches of gears and engineered parts. Whether it’s complete manufacture or modification to off the shelf products such as sprockets, couplings or pulleys, including bore and keyway, broaching and splining.

Phone 0161 737 6969 or email sales@arrowengineering.com to get a quote today!

Machine Shop Capacity

Arrow Engineering’s machine shop is equipped with manual and CNC machinery for Turning, Milling, Gear Cutting, Slotting and Broaching as well as fabrication.

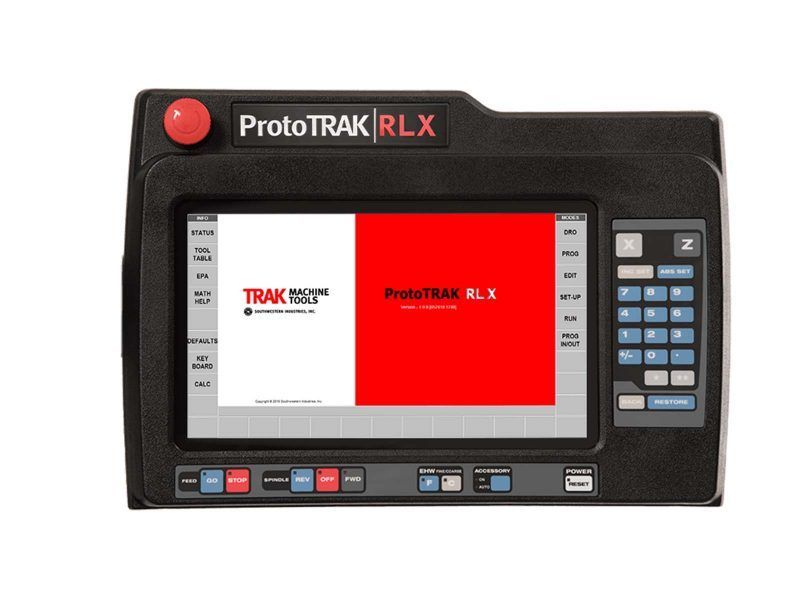

Their CNC Lathes and Milling machines, are predominantly XYZ ProtoTRAK controls. These machines provide “conversational-type” programming with easy touch-screen controls that have simple features where you don’t need as much programming knowledge to that of other traditional CNC programming languages.

The “ProtoTRAK TRAKing” feature gives you the ability to alternate between manual and CNC mode. Using the tracking, electronic handwheels has the reel feel of a manual machine, bringing the power of CNC to your fingertips. Using the “TRAKING” and “GO TO” features help control feed rate and other features in the digital read out, providing safety and saving machine crashes. By carefully using the handles manually to set your programme and then switch to CNC run mode, push “GO” and it will automatically do the machining by itself.

The Lathes and Bed Mills also use DXF Converters which means that Downloads, direct from Desktop to machine are also used.

See below for links to Section. These contain a more in depth look at our machine shop, for your Bespoke Engineering needs:

Turning

CNC Milling

Gear Cutting Cell

Key Seating, Slotting, Splining and Broaching

Fabrication

Solid Works Design

Grinding

On-Site Fitting

Materials Used in Production

Engineering Information:

Turning

Below is a collection of our turning machines:

Large TOS Lathe 4 Meter Bed

XYZ Turning Beds

2 x PROTURN RLX 425

Swing Over Bed 400mm

Spindle Bore 54mm

Distance Between Centres 2500mm

Max 2500 RPM

PROTURN RLX 1630

Swing Over Bed 400mm

Spindel Bore 54mm

Distance Between Centres 760mm Max 2500 RPM

2 x XYZ VL 425 Gap Bed Lathe

257 mm Swing Over Cross Slide

2500 mm Between Centers

VL Control

Rapid setup

Proto-Trak A.G.E

Pro 2000

X=700

Y=320

Z=300

CNC Milling

XYZ BRM 60-100

XYZ RMX 4000

7.5HP Programmable Varbiable Speed Head

1470 x 356mm Table

1016 x 596 x 584 mm Travel Programmable 5000 RPM Spindle

XYZ SMX/RMX 2000

3HP Varible speed head

50″ x 10″ (1270 x 254 mm) Table

30″ x 15″ (762 x 380 mm) Travel

XYZ RMX 3500

5HP Programme Variable Speed Head

1370 x 356 mm Table

787 x 508 x 508 mm Travel

Programmable 5000 RPM Spindle

Gear Cutting Cell

Types of gears that can be cut:

Spur Gears

Helical Gears

Worm Gears

For more information on gears click here.

Norgear Universal Gear Hobber

Universal Gear Hobber, c/w Change Gears, Manual, 500mm Dia x 250mm Face

Sunderland 19 – Cuts Spur gears up to 56” x 9” x 1.5DP (1420mm x 225mm x Mod.16) Helical /Double Helical up to 56” and face width 10” / Spiral gears up to 60 Deg. 1.5” normal pitch / Sprockets up to 54” dia.

Sunderland 5A – Spurs & helicals / 4″ Face – Max – 9 MOD

Sykes V14 Hobber – Helical & Spurs / Max Dia External 13″ / Max Face 8″ / Max Pitch Of Gear 7 D.P. 4 MOD

Barber Colman Hobbers 1 x Type ‘A’ – Spurs & Splines Max 12″ Dia

Barber Colman Hobbers 1 x Type ‘D’ – Spurs & Helicals – Max 3 D.P x 14″ Dia

Barber Colman Hobbers 1 x No.3 – Spurs & Helicals – Max 6″ Dia

Key Seating, Slotting, Splining and Broaching

Internal Splines

External Splines

Slotting

Broaching

Key Seating

Lunn Davis Key Seating Machine

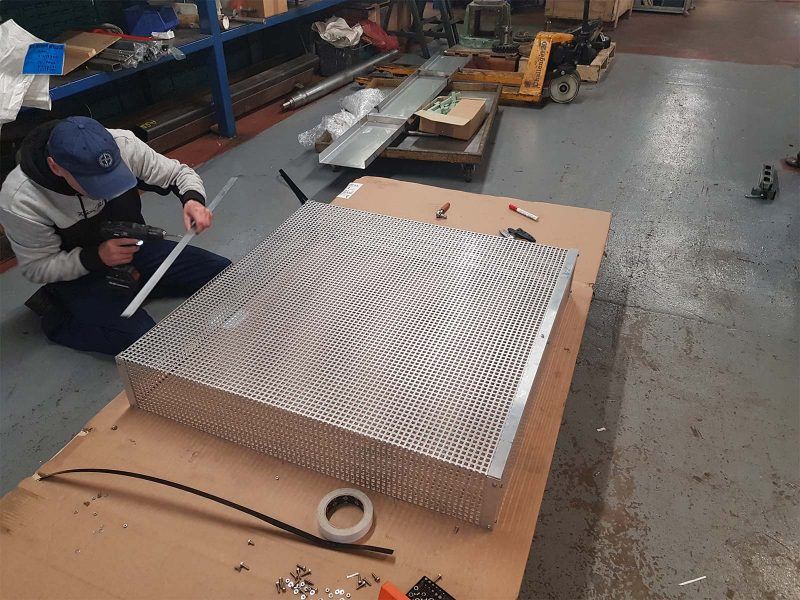

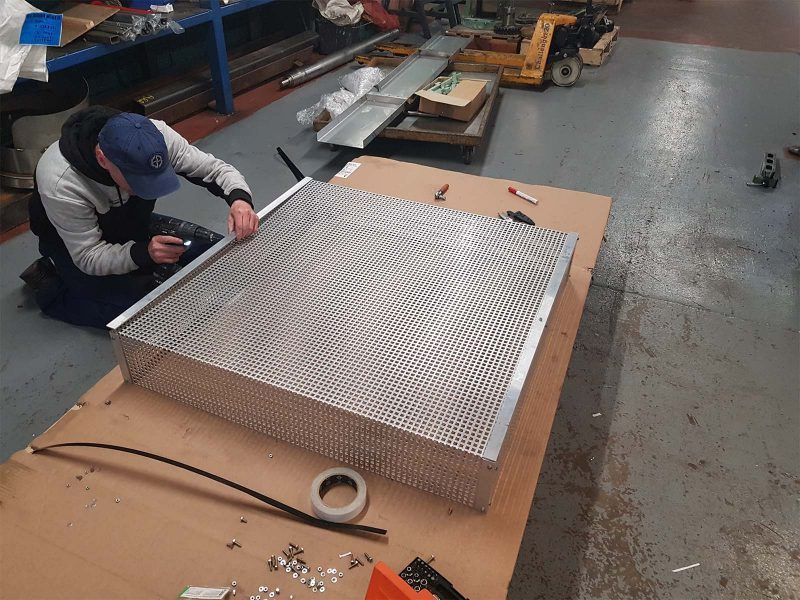

Fabrication

We fabricate all shapes and sizes of guards and enclosures in metals (Stainless Steel, Mild Steel and Aluminium Sheet steel) and Acrylic / Polymers (Polycarbonate, Plastic, Acetal, Polyethylene, Tufnol, and PVC.

Welding

Capacity for Tig Welding and Mig Welding

Cutting

Bending, Folding and Forming

Machining of Parts in conjunction with Fabrication

In conjunction with our machine shop we can Turn, Mill and Gear Cut special products such as Brackets, Shaping rings, Scrapers, Dough Ball Divider segments, Nib Tensioning Rollers and special gears.

CAD Design

Our CAD Design Technicians are capable of producing intricate CAD Drawings from Sample Components, Customer Descriptions or Sketches.

Use of the latest version of SolidWorks allows us to produce complex 3D Models and Assemblies which in-turn enables us to prototype any new design or requirement as well as offering the ability to amend the designs of existing components.

We actively maintain a drawing library of our clients’ drawings and, where possible list the machinery name, number and any revisions to existing designs, enabling our clients to request repeat orders without the hassle of repeatedly dispatching sample parts.

The 3D Models which we produce can be 3D Printed and the CAD Drawings we produce can be easily integrated into our CNC Machinery to further improve our accuracy.

Why not have a look through our gallery of some of our 3D models as well as their finish machined counterparts. View our Quality Policy.

Grinding

Jones & Shipman 1400 Surface Grinder

24″ x 8″ Magnetic Base

On-Site Fitting

Safety Passport Alliance / fully qualified fitters / conforming to the latest health and safety standards.

Materials Used in Production

Mild Steels, Cast Iron, Aluminium, Stainless Steels, Super Duplex, Nickel Alloys, Nimonic, Inconel, Titanium, Monel, Copper, Brass, Bronze.

Polymers Used in Production: Nylon, Acetal, Polyester, Polypropylene, Polyethylene, Peek, Delrin, PTFE

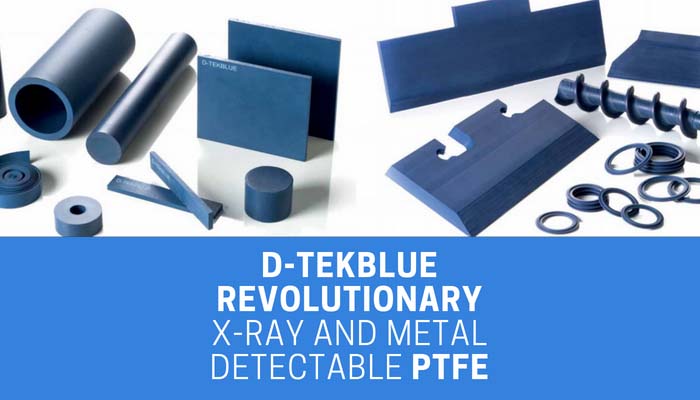

Special Polymers

Special Polymers provide strength and Design, Manufacturing Flexibility

Arrow Engineering have been manufacturing parts in special Polymers for many applications specifically in the Pharmaceutical, Food / Baking, Bottling and Brewing industries.These special impregnated PTFE and Graphited polymers therefore they are a great alternative sometimes to parts manufactured in Metal.

Polymers weigh less, they don’t corrode and are less expensive than metal made parts. Primarily they are much less expensive to produce because they allow more flexibility within the design and manufacturing process.

Thus less complex machining operations, for example, no coolant necessary and less wear on tooling and longer tool life. Special impregnated Polymers provide comparable high tensile strength to metals and have the advantage of being lighter in weight.

Many aerospace, automotive and railway applications have replaced metal parts with plastics and special polymer manufactured parts.Besides being able to machine Polymers. Arrow also have 3D printing capabilities which enable one off prototype’s to be made before investing in large batch quantities.

Take a look at the machine shop capacity and some of the parts we have manufactured in our Job Gallery.

PTFE For Food and Drink

We are now proud to announce the use of Special Filled PTFE materials in conjunction with Guarniflon.

Food and Beverage process industries require high speed high temperature processes to meet the demands mass production requirements of Super Markets and Fast-Food outlets.

Hydraulic, Pneumatic and Mechanical parts are pushed to their limits. Causing inevitable wear quicker in these non-stop, multi shift food and beverage production applications.

We’ve been manufacturing mechanical parts for the Food industry for over 40 years. Instead of using standard materials such as Stainless Steel (316) and Polymers including Acetal and PTFE.

The manufacturing of Bushes, Scrapers, and Special Seals for Mixers, Agitators, Valves and Cylinders with food safe Glass Filled PTFE.

Importantly at Arrow we can now offer a new range of products manufactured with special Filled PTFE with the alternative fillings:-

TEKCLEAN

PTFE G673

D-TEKBLUE