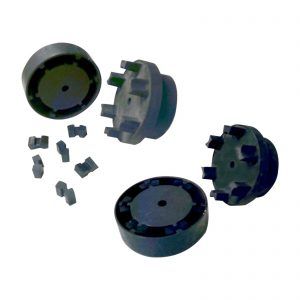

NUPEX (NPX)

NUPEX (NPX) – Designed to industry standard. Available with three-part flanges, thus allowing the segments to be changed without disturbing either the driving or driven shaft. High levels of torsional flexibility. High speed capability. Suit IEC electric motor applications. Taper bore and pilot bore flanges.

NPX Coupling Selection Procedure

Based on Power and Speed

• Step 1) Service Factor, from the table below select the service factor that is appropriate for the application.

• Step 2) Design Power, multiply the absorbed power, kW, of the driven machine by the service factor from Step 1 to obtain the design power. If the absorbed power is not known, use the prime mover power.

• Step 3) NPX coupling size selection, refer to the bottom table. Read down the left-hand vertical column to the required speed. Interpolate if the exact speed is not listed. Read horizontally across on the speed line until a power equal to or in excess of the design power, from Step 2), is reached. Read vertically to the top of the column to obtain the correct size of the NPX coupling.

• Step 4) Bore dimensions, from the dimensions table found on individual products, check that the selected coupling will fit the shafts.

Based on IEC Electric Motors – Click here for the IEC Page

• Step 1) Note the frame size of the motor, power, speed (or number of poles).

• Step 2) Read across to the column headed by the motor speed (or number of poles).

• Step 3) The next column to the motor power gives the size of NPX coupling required. Pilot bore flange sizes are in normal type face. Taper bore flanges are in italic.

We have an extensive product range as well as the capacity to make product modifications (In-House Engineering). At your request we even manufacture unusual items. For non-standard alterations or item manufacture Click Here.

For help selecting the right Coupling suited to you, please Click Here to visit the Frequently Asked Questions page.