Measuring, identifying, and manufacturing small intricate gears from sample can be quite difficult especially when the samples provided are damaged, with hardly any teeth left. Arrow Engineering have a wealth of knowledge and experience of identifying gears and working these things out.

A vinyl floor manufacturer was experiencing downtime due to a gearbox failure and needed a replacement gearbox or a repair to get them back up and running.

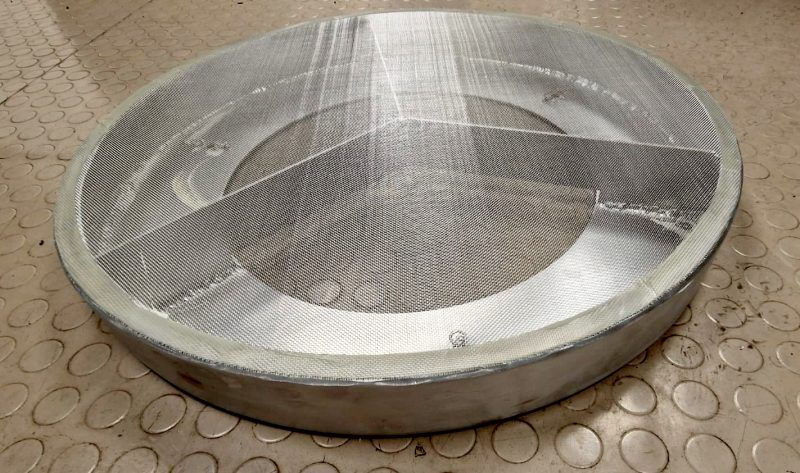

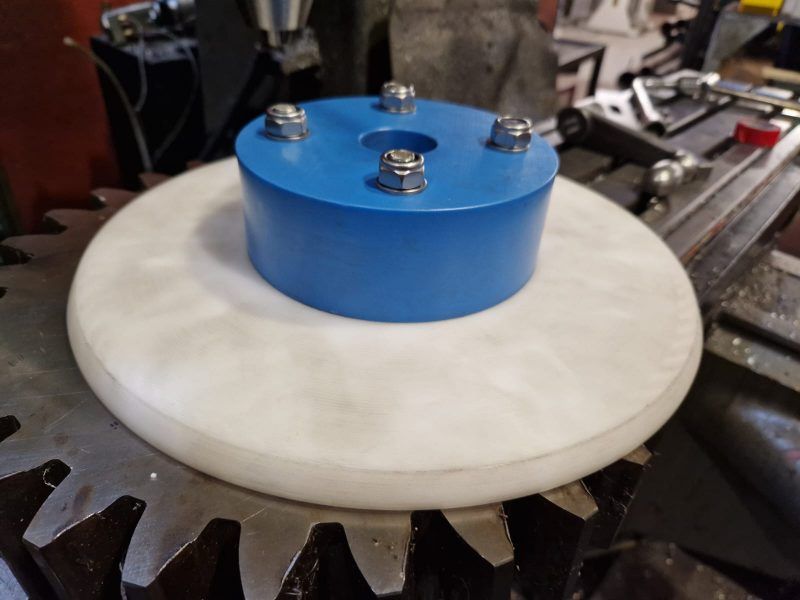

The Tension Drive Gearbox that maintained the tension in sheet of the Vinyl Flooring whilst being produced had stopped driving. Upon inspection it was found that the mating gears had failed which meant that 2 Helical Gears needed to be made in a hurry.

The gearbox was collected Friday night, stripped down, the gears were manufactured on Saturday Hardened on Sunday and re-assembled. The Tension Station flooring conveyor was back up and running by Monday lunchtime.