32B 17Tooth Double Duplex

Besides carrying stocks of standard sprockets, Arrow also make bespoke sprockets. These 2” Pitch 17 tooth Double Simplex Sprockets, were cut on Arrow’s Sunderland 19.

32B 17Tooth Double Duplex Read More »

Besides carrying stocks of standard sprockets, Arrow also make bespoke sprockets. These 2” Pitch 17 tooth Double Simplex Sprockets, were cut on Arrow’s Sunderland 19.

32B 17Tooth Double Duplex Read More »

The launch of a new biscuit, from a leading manufacturer was threatening to be delayed due to a long lead time from Italy of a special wear guide for a conveyor.

Arrow Engineering were able to produce this within 2 weeks, in time for the installation of the new Biscuit Conveyor Belt.

Three pairs of 1240mm long, Left Hand and Right Hand, special profile Wear Guides, were manufactured in PET Polymer by our XYZ BRM 60/100 Bed Mill

Wear Guide for new Biscuit production line Read More »

Just to let you know that we regularly repair Sieve Mesh frames and can provide a quick service and up to a 40% saving against new Sieve frames.

The replacement Stainless Steel Wire Mesh is available off the shelf in different apertures and is securely fixed using a food safe structural epoxy resin.

When you are next looking for replacement Sieve Mesh Frames

Repair / Replacement Sieve Mesh Frames 40% saving against buying new Read More »

Measuring, identifying, and manufacturing small intricate gears from sample can be quite difficult especially when the samples provided are damaged, with hardly any teeth left. Arrow Engineering have a wealth of knowledge and experience of identifying gears and working these things out.

A vinyl floor manufacturer was experiencing downtime due to a gearbox failure and needed a replacement gearbox or a repair to get them back up and running.

The Tension Drive Gearbox that maintained the tension in sheet of the Vinyl Flooring whilst being produced had stopped driving. Upon inspection it was found that the mating gears had failed which meant that 2 Helical Gears needed to be made in a hurry.

The gearbox was collected Friday night, stripped down, the gears were manufactured on Saturday Hardened on Sunday and re-assembled. The Tension Station flooring conveyor was back up and running by Monday lunchtime.

The little ones are the tricky ones Read More »

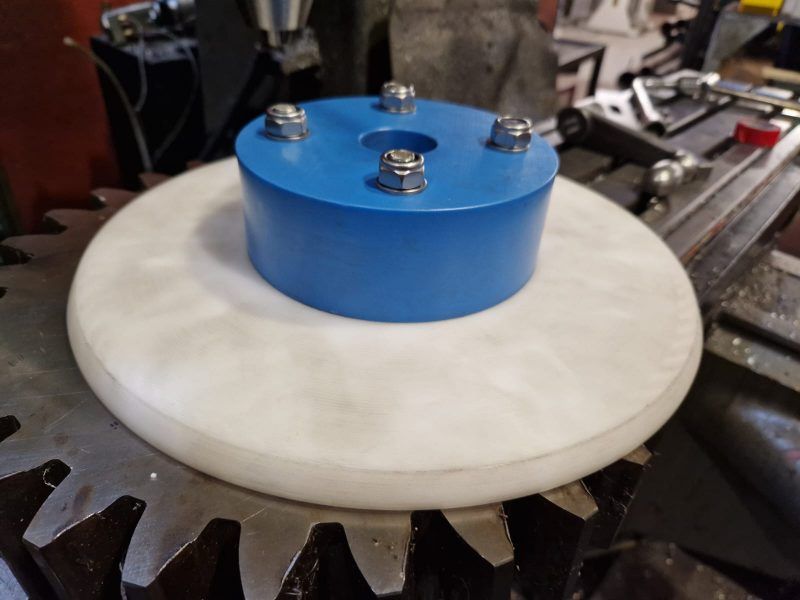

A bakery experienced a conveyor breakdown where the belt had tracked to one side causing it to snag and jam, breaking the Mesh belt support rods. Arrow Engineering were called in on Friday at 5pm with the need to get the drive back up and running. As a quick fix a 295mm Acetal disc was turned and bolted to the existing hub, which stopped the belt riding up and over the conveyor wheel, 40 rods were turned and supplied over the weekend and the belt was back up and running for Monday.

Modify conveyor Wheel increase O.D. to 295mm chamfer one side, bolt to existing boss Read More »

We regularly make special sprockets for modular belts because they are on a long lead time from Germany or Italy. These sprockets were made to sample for a local Bakery.

Sprockets were made to sample for a local Bakery Read More »