LM35 Non-Sparking Complete Coupling

LM35 Complete Metallic Disc Coupling (Non-Sparking)

- Used where the electrically insulated couplings are required.

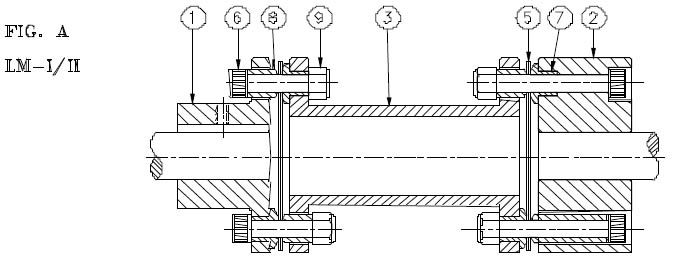

1) Adapter 1, 2) Adapter 2, 3) Spacer, 5) Discs, 6) Socket Head Cap Screws for Discpack, 7) Bushes, 8) Sleeves, 9) Nylon Nuts

Assembly Procedure for LM Type Couplings

Clean all the parts carefully. 1) Support the spacer between two adapters in such a way that the clear holes of spacer flange will be in line with the press fitted bushes in the adapter. 2) Hold the flexible membrane between the adapters & spacer flanges. 3) Insert socket head cap screws with sleeves from adapter side through the clear holes of adapters, membrane holes & press fitted bushes on spacer and tighten the nylock nut. 4) Then insert the socket head cap screws from adapter side through the press fitted bushes in the adapters, membrane holes and clear hole on spacer flange. Insert the sleeve from spacer side & tighten the Nylock nut. 5) Follow the same procedure from other side also. Then tighten all the nylock nuts to the required tightening torques for disc pack bolts given in the table. 6) Ensure the Gap ‘G’ is equal at both sides of spacer. Value of gap ‘G’ is given in table 1 & 2. Tighten the foundation bolts of both equipments.

Important: If the coupling is dynamically balanced, ensure that the matchmarks are in a straight line & unidirectional before bolting the assembly. The necessity for shields & guards varies with individual installations. The owner or user must provide the required safety guards or shields are not furnished by us with this equipment.

Please also see our In-House Machining Services for your boring/keying needs, alternatively please click here to send us an email enquiry. Note: All dimensions are in mm unless otherwise specified. Non Standard DBSE available on request. Please specify type of adapters (1/1, ½ or 2/2). Weight, M.I. & Stiffness are at max bores with min. Std. DBSE with one type 1 and one type 2 adpt. Available for non-sparking applications on request. Specified max speeds are without balancing. With balancing, speeds can be increased – please consult us in your email enquiry. Additionally, please click here to view the catalogue for further information.

Reviews

There are no reviews yet.